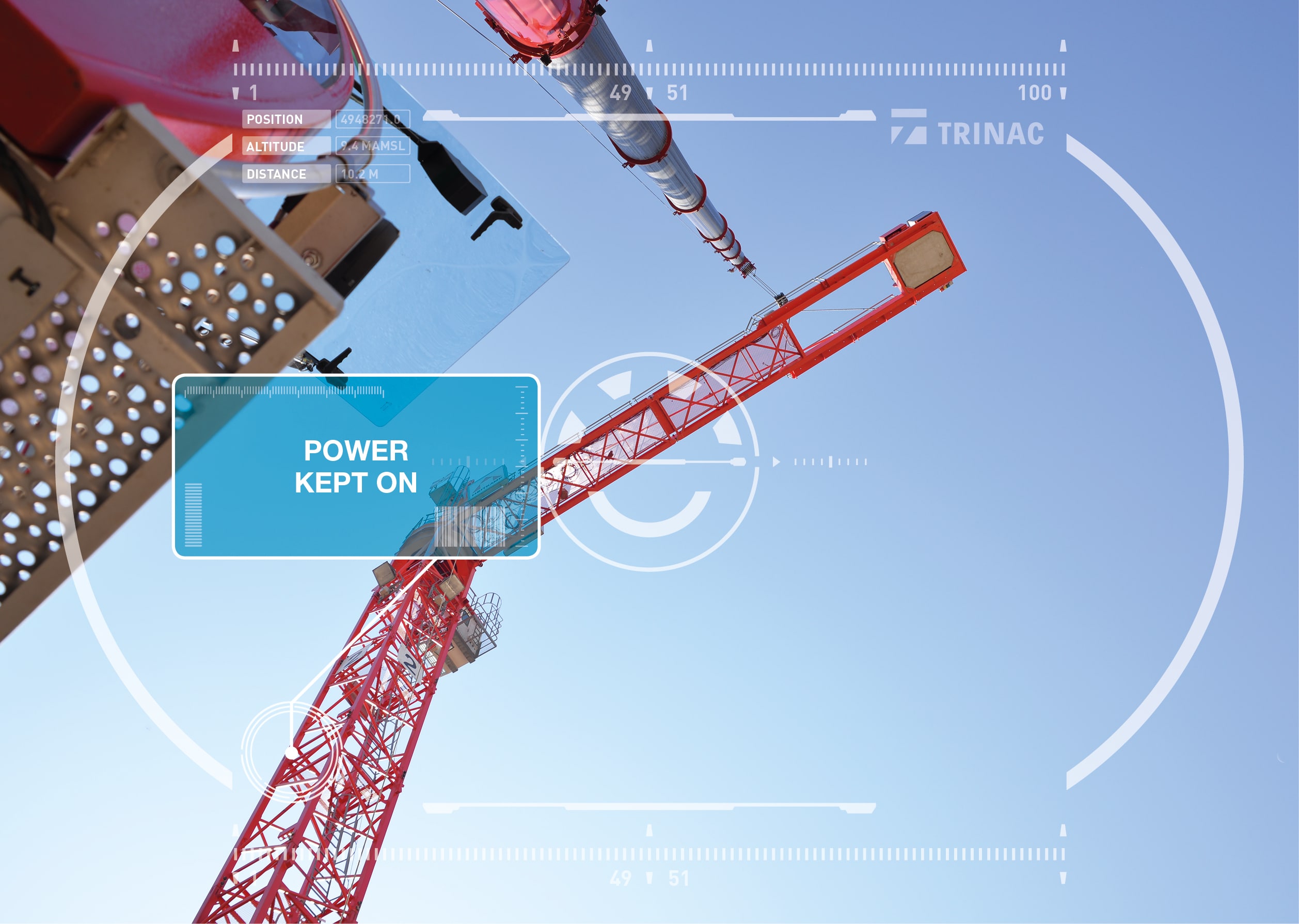

The new shopping center in Dresden will be easy to reach for its customers. Unfortunately this was not the case for the construction site and providing cranes there. Two main highways and double-track tramlines with their overhead power cables made setting up the cranes a real logistical challenge. Cranes with load bearing capacities of up to 20 tons were required for operating the construction site covering an area the size of a soccer pitch. Our concept involved a Wolff WK8540 with 55 meters working radius and a hook height of 33 meters, a Liebherr 550 EC-H 20Li with 60 meters working radius and 65 meters hook height and a Liebherr 630 EC-H 20Li with 70 meters working radius and a hook height of 53.7 meters.

DRESDEN

Pure logistics – the tram remains punctual.

It was not possible to dismantle the overhead cables for the tramway and close off the important transport arteries. We therefore decided to assemble the cranes using a 400-ton mobile crane, which was positioned at the bottom of the construction pit. The assembly functioned perfectly according to plan in the same way as the entire shell construction, which had already been completed after six months. This meant we faced the next challenge: dismantling. Because now no mobile crane was able to operate from the construction pit, and road traffic could also not be blocked on the very busy Antonstraße. We found a solution to dismantle the Wolff WK8540, the Liebherr 630 EC-H 20Li and the Liebherr 550 EC-H 20Li without cordoning off the road.

We achieved this through staggered descent and favorable positioning of a mobile crane between the building and Königsbrücker Straße. The overhead cables remained unaffected, and the tram and the pre-Christmas road traffic continued uninterrupted.

What to do when there is too much electricity in the air?

In Dresden high-voltage cables which were also essential blocked the air space above the site. This was above all the case during dismantling because there was no longer a construction pit available with space for the mobile crane. The solution was staggered descent until a mobile crane could deal with the remaining work from outside the construction site.